Designing a sturdy water process that continuously makes superior-excellent product or service water is important for pharmaceutical producing procedures.

Running Strategies— Treatments for running the water procedure and carrying out program upkeep and corrective action really should be published, plus they must also define The purpose when action is required. The strategies should be effectively documented, depth the operate of each and every job, assign who's to blame for undertaking the perform, and describe how The task is to be performed. The performance of those procedures must be assessed throughout water program validation. Monitoring Plan— Significant top quality characteristics and functioning parameters must be documented and monitored. This system may well contain a combination of in-line sensors or automatic devices (e.g., for TOC, conductivity, hardness, and chlorine), automatic or handbook documentation of operational parameters (for instance stream charges or force drop across a carbon mattress, filter, or RO unit), and laboratory assessments (e.g., complete microbial counts). The frequency of sampling, the requirement for assessing examination results, along with the necessity for initiating corrective action should be incorporated. Sanitization— Based on process design and the selected units of Procedure, schedule periodic sanitization could be essential to sustain the method in a condition of microbial Command. Systems for sanitization are explained earlier mentioned. Preventive Servicing— A preventive routine maintenance program really should be in result. The program should really set up what preventive maintenance should be to be executed, the frequency of servicing operate, And exactly how the get the job done really should be documented. Improve Manage— The mechanical configuration and working situations have to be managed. Proposed alterations needs to be evaluated for his or her influence on the whole process. The need to requalify the process soon after improvements are made need to be established. Adhering to a choice to switch a water program, the affected drawings, manuals, and strategies should be revised. SAMPLING Things to consider Water units ought to be monitored at a frequency that's sufficient to make certain the technique is in control and carries on to supply water of appropriate high quality.

It maintains the feed water temperature beneath twenty five ºC with the help of Chilled Water on the opposite side of plates in the course of typical service cycle.

Ordinarily, number of complications are encountered in keeping the chemical purity of Purified Water and Water for Injection Nevertheless, the arrival of working with conductivity and TOC to define chemical purity has permitted the user to extra quantitatively evaluate the water's chemical purity and its variability being a functionality of program pretreatment method servicing and regeneration. Even the existence of these kinds of device functions as warmth exchangers and use level hoses can compromise the chemical excellent of water inside of and delivered from an if not very well-controlled water technique. As a result, an evaluation of the regularity from the water's chemical purity as time passes have to be A part of the validation system. Having said that, even with quite possibly the most effectively controlled chemical high-quality, it is commonly more difficult to constantly satisfy founded microbiological top quality conditions owing to phenomena happening through and following chemical purification. A normal software entails intensive day-to-day sampling and testing of major course of action factors for at least just one thirty day period soon after operational conditions have already been established for each device Procedure, place of use, and sampling point.

Sterile WFI is often packaged in single-dose containers that are generally less than one L in size.

As course of action Command indicators, notify and motion concentrations are created to enable remedial action to come about that will reduce a procedure from deviating absolutely uncontrolled and developing water unfit for its intended use. This “supposed use” minimum amount good quality is sometimes often called a “specification” or “Restrict”. Inside the opening paragraphs of the chapter, rationale was introduced for no microbial specs becoming incorporated within the physique of the bulk water (Purified Water and Water for Injection) monographs. This doesn't signify that the person must not have microbial technical specs read more for these waters. On the contrary, in many circumstances this sort of requirements must be set up from the person. The microbial specification ought to replicate the most microbial level at which the water remains to be fit to be used devoid of compromising the quality requirements of the process or item in which the water is used. Simply because water from a presented system may have many uses, by far the most stringent of these employs need to be used to determine this specification. In which appropriate, a microbial specification could be qualitative along with quantitative. Put simply, the number of whole microorganisms might be as essential as the number of a certain microorganism or simply the absence of a specific microorganism. Microorganisms which can be regarded to become problematic could incorporate opportunistic or overt pathogens, nonpathogenic indicators of doubtless undetected pathogens, or microorganisms recognized to compromise a method or products, for example by currently being immune to a preservative or capable to proliferate in or degrade a product. These microorganisms comprise an normally unwell-outlined team called “objectionable microorganisms”. Simply because objectionable is usually a expression relative towards the water's use, the list of microorganisms in this kind of a bunch ought to be tailored to those species With all the likely to get existing and problematic. Their negative impact is most frequently demonstrated when they are existing in significant numbers, but depending on the species, an allowable degree may possibly exist, underneath which they might not be considered objectionable.

The investment will likely assist enhance our environmental footprint at the Karlskoga web site,” clarifies Sandberg. Cambrex also a short while ago concluded an update of wastewater handling abilities at its Milan, Italy manufacturing facility, he studies.

Other Manage procedures include things like the usage of ultrafilters or charge-modified filters, possibly in-line or at the point of use. The presence of endotoxins may very well be monitored as explained in the general check chapter Bacterial Endotoxins Check

Assembly these microbiological needs does not rule out the presence of other microorganisms, which could possibly be regarded as unwanted if present in a drug material or formulated products.

Developing implantable health-related gadgets: Biomedical manufacturers use WFI to create implantable health-related devices and make sure sterility.

Bradley: Perfectly the USGS Toxic Substances Hydrology Program has actually been conducting many different countrywide surveys over the past ten years. And the outcome of such various experiments implies that, that rising contaminants are literally common from the environment and they're found in rivers and streams across the country.

It is also ironical that the character of many of the sluggish growers as well as the extended incubation times desired for his or her enhancement into seen colonies may additionally bring on People colonies being mainly nonviable, which limitations their further characterization and precludes their subculture and identification.

Purified Water must fulfill the necessities for ionic and natural chemical purity and have to be protected against microbial contamination.

These strategies ordinarily hire oxidizing water for pharmaceutical use agents including halogenated compounds, hydrogen peroxide, ozone, peracetic acid, or combos thereof. Halogenated compounds are successful sanitizers but are hard to flush in the system and should leave biofilms intact. Compounds such as hydrogen peroxide, ozone, and peracetic acid oxidize microbes and biofilms by forming reactive peroxides and absolutely free radicals (notably hydroxyl radicals). The limited half-lifetime of ozone specifically, and its limitation on achievable concentrations demand that it's additional repeatedly in the course of the sanitization procedure. Hydrogen peroxide and ozone fast degrade to water and oxygen; peracetic acid degrades to acetic acid while in the existence of UV mild. In fact, ozone's simplicity of degradation to oxygen applying 254-nm UV lights at use points make it possible for it to become most efficiently used over a constant foundation to provide consistently sanitizing situations.

Kel Mitchell Then & Now!

Kel Mitchell Then & Now! Joseph Mazzello Then & Now!

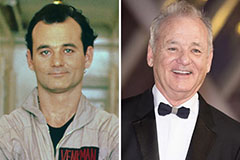

Joseph Mazzello Then & Now! Bill Murray Then & Now!

Bill Murray Then & Now! Christy Canyon Then & Now!

Christy Canyon Then & Now! Nicki Minaj Then & Now!

Nicki Minaj Then & Now!